To source iron-on patches wholesale from China, define your specs, contact verified factories (not just traders), approve physical samples, and negotiate on both price and quality control.

With fast production cycles, a variety of styles, and low MOQs, China is the global go-to hub for patch sourcing—from fashion brands to team merch.

Why Buy Iron-On Patches from China?

China offers unmatched scalability, pricing, and product diversity in patch manufacturing.

Key Advantages

- ✅ Low unit cost—even for 100–500 pcs

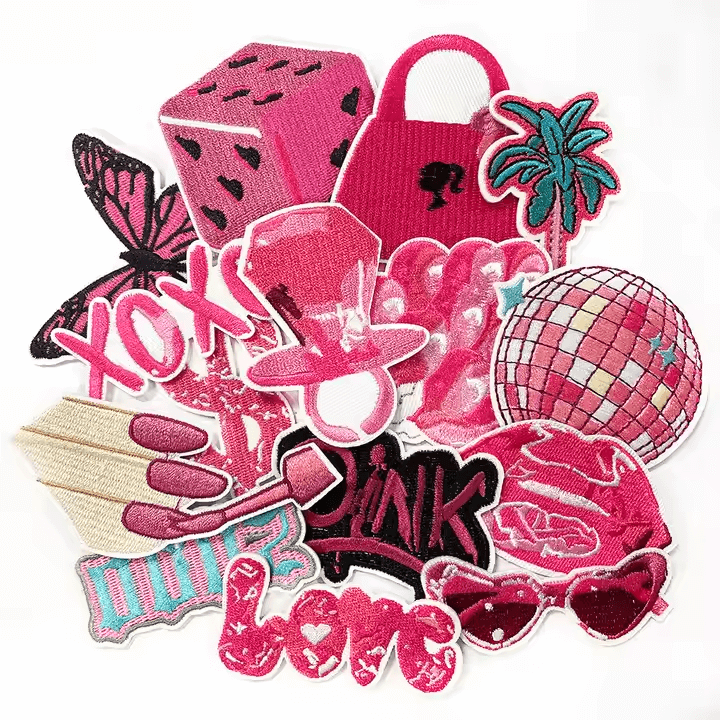

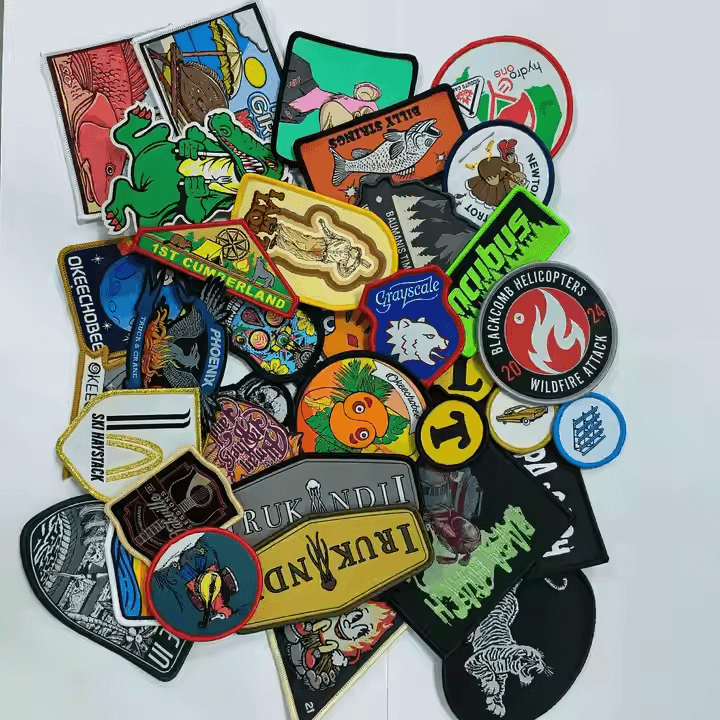

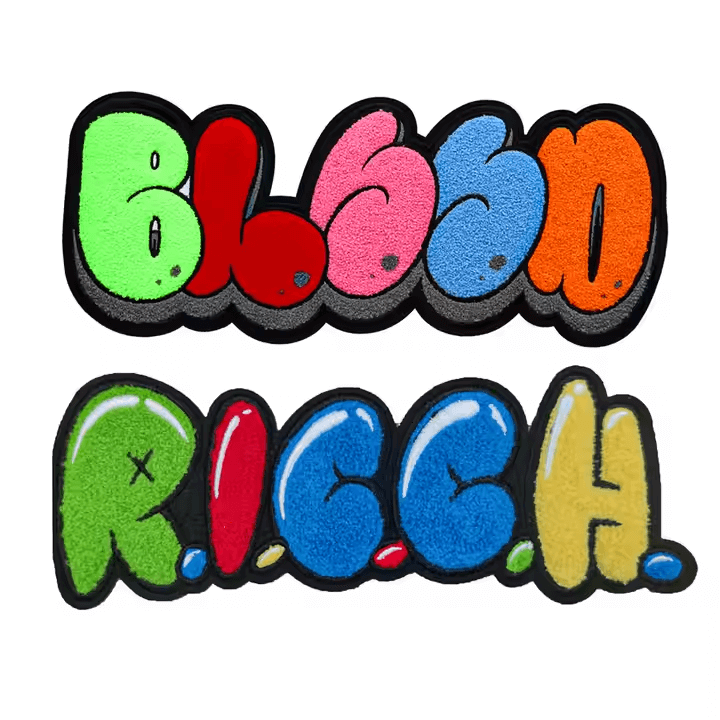

- ✅ Diverse patch types: embroidery, PVC, chenille, heat transfer

- ✅ Fast sampling (3–7 days typical)

- ✅ Mature logistics & export compliance

🇨🇳 China exports iron-on patches to 80+ countries annually, powering Shopify stores, Etsy brands, uniforms, and gift merch.

What Types of Iron-On Patches Can You Source?

Iron-on patches differ by texture, durability, and usage. Choose based on your audience and fabric.

| Patch Type | Key Features | Best For 1 |

|---|---|---|

| Embroidered | Textured, raised threads | Uniforms, jackets, hats |

| PVC / Rubber | Waterproof, 3D look | Outdoor gear, bags, tactical use |

| Heat Transfer | Flat, printed surface | T-shirts, fashion drops |

| Chenille | Fluffy, retro style | Varsity jackets, streetwear |

| Silicone | Soft, flexible, matte | Shoes, sportswear, lifestyle |

🎯 Backings to Know

- Standard heat adhesive (180–200°C press)

- Low-temp glue (for synthetics)

- Dual back (iron-on + sew-on)

Where Can You Find Reliable Suppliers in China?

Use trusted B2B platforms or agents—but validate every supplier before paying.

Sourcing Channels Comparison

| Source 2 | Pros | Cons |

|---|---|---|

| Alibaba | Reviews, Trade Assurance | Many traders, mixed quality |

| 1688 | Lowest prices (factories) | Chinese-only, agent needed |

| Trade Shows | Product feel, face-to-face | Only seasonal, travel cost |

| Sourcing Agents | Language & logistics help | Fees added, needs trust |

📍 Key Production Areas:

- Yiwu – small decorative embroidery

- Guangzhou – woven/embroidered patches

- Wenzhou – silicone, PVC, industrial patches

Step-by-Step Sourcing Process

A structured approach ensures you avoid delays, defects, and lost money.

Proven Workflow

- Prepare clear spec sheet + design file (AI preferred)

- Contact 3–5 suppliers, compare pricing

- Approve sample (iron-on + design accuracy)

- Finalize PO and deposit (30%)

- Receive production updates (photos/videos)

- QC & balance payment (70%)

- Arrange shipping and delivery tracking

📦 Sample Checklist

- Logo stitching and color match

- Backing glue test (iron press)

- Edge type (merrowed or laser-cut)

- Felt, twill, or polyester base confirmed

Common Sourcing Pitfalls to Avoid

Many new buyers lose money or time due to avoidable mistakes.

Top Mistakes

- ❌ Skipping sample approval

- ❌ Not clarifying glue type or edge style

- ❌ No QC clause or rework terms in PO

- ❌ Paying 100% upfront

- ❌ Ignoring factory audit or past reviews

- ❌ No IP agreement = risk of copied designs

🛡️ Pro Tip: Ask for NDA + “not for resale” clause in the purchase contract.

Cost Structure & Smart Negotiation Tips

Understand how pricing works so you can negotiate more than just cents.

Cost Breakdown

| Item 3 | Description |

|---|---|

| Unit Price | Based on patch size + complexity |

| Setup Fee | One-time mold (for embroidery/PVC) |

| Packaging | Bulk bag, individual bag, labeled |

| Sample Cost | $10–$50 (refundable or not) |

| Shipping | Courier (DHL), freight, sea |

Negotiation Tips

- Ask for sample refund on PO

- Bundle SKUs for price break

- Emphasize long-term volume

- Lock lead time + QC terms in writing

Shipping & Customs for Iron-On Patches

Choose shipping based on weight, budget, and urgency.

| Method | Ideal Volume | Lead Time |

|---|---|---|

| Express (DHL) | 3–7 days | |

| Air Cargo | 20–100kg | 5–10 days |

| Sea Freight | >100kg | 25–40 days |

📑 Required Docs:

- Commercial Invoice

- Packing List

- HS Code:

58109100(embroidery) /39269090(PVC) - Optional: Certificate of Origin, Form A, Bill of Lading

Best Practices to Build Long-Term Partnerships

Reliable factories offer better prices, faster sampling, and smoother reorders.

Partnership Framework

- Build rapport on WeChat for smoother updates

- Give consistent feedback on sample & packaging

- Share forecasts to unlock volume pricing

- Use supplier scorecard: quality, comms, speed

- Reward reliable suppliers with loyalty—not just low prices

🤝 Good relationships = better pricing, faster service, and production priority.

Conclusion: Your Iron-On Patch Sourcing Action Plan

China is the ideal place to source wholesale iron-on patches—but only if you follow a structured process.

-

To Helps match patch types to target consumer groups. ↩

-

To Ensures readers avoid scams and improve outcomes. ↩

-

To Protects buyers with delivery and quality guarantees. ↩