What items need to be tested for woven fabrics?

According to the process classification, there are basically only two types of clothing fabrics, woven fabrics and knitted fabrics. For these two types of fabrics, except for the technical indicators of dyeing fastness and chemical properties, the test items of physical properties are very different. Woven fabrics can be tested for relatively more items. Due to its structure, knitted fabrics can be tested for relatively less items. The following is a classification and explanation of the daily test items of woven fabrics to see which fabrics need to be tested for which items, so as to carry out targeted product quality monitoring. The test items for woven fabrics are: A. Organization structure test This type of test is the basic requirement for finished products, including: fiber content, yarn density (thickness), twist, density, weaving classification, (organization structure), gram weight, thickness, fabric width and effective width. B. Tensile properties include tensile breaking strength, tensile breaking elongation, tearing breaking strength,

seam performance (seam slippage or cracking, seam strength, seam efficiency), tensile elastic elongation and recovery, ball bursting strength, hydraulic bursting strength. C. Structural stability: dimensional stability under various conditions, including: washing, dry cleaning, dry heat, steaming, soaking, and ironing. Distortion rate after washing (including distortion after dry cleaning or washing) Appearance flatness (assessment of creases after dry cleaning or washing) D. Appearance performance Wear resistance, color change after wear, pilling performance, drape, wrinkle recovery, anti-snagging performance E. Additional functional performance Breathable performance,

moisture absorption and quick drying performance, moisture absorption and perspiration performance, antistatic performance, flame retardant performance, surface waterproofness, hydrostatic pressure resistance, oil repellency, easy decontamination performance, moisture permeability, thermal insulation performance, UV resistance, low temperature resistance, mosquito and insect resistance, anti-mite performance, contact coolness performance, far infrared temperature rise, heat shielding performance, near infrared spectral reflection, etc. All of the above are common in fabrics, and there are many functions that we textile people need to continuously develop; do all fabrics need to be tested for these properties? We know that quality requires a lot of cost. How to achieve precise control and reduce costs; we need to understand fabrics, testing methods, and customer needs, so as to appropriately reduce costs, avoid unnecessary testing costs, and improve testing efficiency.

Description of test items for tissue structure

[Fiber content]● Importance of testing: It is mandatory to test the fiber composition or content; this is to satisfy the consumer’s right to know, what materials are used to make the clothing or fabric, and what is the percentage of each material; so that consumers can choose, maintain and take care of the goods according to their own needs and hobbies. Correctly marking the fiber content is an essential and must not be neglected thing on every piece of clothing. For fiber content testing, it is best to test the finished product after the fabric is produced, or use ready-made clothes for testing; in this way, a more accurate fiber content percentage can be obtained. For those fabrics with coatings and films, the coatings and films need to be removed to obtain a more accurate fiber content. Some foreign customers may also need to separately standardize: the composition and percentage content of the coating or film, and then the percentage content of the fiber in the fabric. The fiber content test is mainly: through physical methods, such as cotton and linen blends, wool and cashmere blends, the chemical properties of these fibers are similar, and it is difficult to distinguish them by chemical dissolution methods; they can only be counted one by one under a microscope, and then their percentage content is calculated. Products containing spandex can be processed by chemical dissolution and manual separation. The manual separation method is time-consuming and labor-intensive, but the test results are relatively stable; the chemical method may have large deviations depending on the specific composition of the fabric. Chemical dissolution method: Depending on the type of fiber, the chemical properties presented are also different. It is used at different temperatures, different chemical reagent concentrations, and different dissolution times to dissolve one fiber; and another fiber is left; if there are three or more components, it can be processed by combining physical and chemical methods. From the perspective of testing techniques alone, the test of chemical methods has obvious and high technical requirements to ensure the accuracy of the test results; the deviation is also larger than that of manual methods. In the production process, dyes, finishing agents, alkali treatment, etc., all of which have a certain solubility or adhesion to the fiber; these substances will affect the percentage of fiber content during the test process. [Misunderstanding] Directly use the raw yarn ratio as the final fiber content; the raw yarn ratio is only the initial feed ratio of the raw materials, and cannot represent the fiber content of the finished product. This is a common phenomenon for many spot fabrics; when purchasing spot fabrics, it is still necessary to test the composition of the fabrics. [Precautions] A. Name The fiber name, as stipulated by our country, must comply with two standards: GB/T 11951-2018 “Natural Fiber Terminology” and GB/T 4146.1-2020 “Textiles Chemical Fibers Part 1: Generic Names”. Only professional names that appear in these two standards can be marked on product tags and wash labels. New names that do not appear or names named by the manufacturer will be treated as non-compliant. B. Technical requirements are based on the national standard GB/T 29862-2013 “Fiber Content Identification”. When a product or a part of a product is composed entirely of one type of fiber, “100%”, “pure” or “full” is used to indicate the fiber content, and the fiber content tolerance is 0. Expressed as: 100% cotton; containing ≤0.5% of other fibers, which can be a single fiber or the total amount of two or more fibers, it is expressed as: 100% cotton (containing trace amounts of other fibers); the product or a part of the product contains what can be judged as decorative threads or characteristic fibers (for example, elastic fibers, metal fibers, etc.); it is expressed as: 100% cotton (excluding decorative threads); ● When a product or a part of the product contains two or more fibers, except for the fibers that are not marked as permitted by the standard, the tolerance of the content of each fiber indicated on the label is 5% (for example: label content: 40% cotton/40% polyester/20% nylon, allowed content: 35%~45% cotton/35%~45% polyester/15%~25% nylon), and the tolerance of the fiber content of the filler is 10%. ● When the content of a certain fiber is less than 10%, the fiber content tolerance is 3%; when the fiber content of the filler is less than 20%, the fiber content tolerance is 5%; ● When the content of a certain fiber is less than 3%, the actual content shall not be 0. When the fiber content of the filler is less than 5%, the actual content shall not be 0. ● When the content of a certain fiber or the total amount of two or more fibers is less than 0.5%, it can be excluded from the total amount. If applicable, it can be marked as “contains trace amounts of XX” or “contains trace amounts of other fibers” (same as the first treatment).

[Yarn Linear Density] ● Importance of Detection: Selective Testing ● Technical Requirements: Recommended ±5% Note: If the standard requirements are not specified, it only represents the personal experience since the industry (the same below). Except for wool, cashmere, and fine cotton yarn, which are fabrics that are more sensitive to fineness, other types of fabrics are rarely tested, and it is rare to see relevant technical requirements for yarn line density in fabric or garment product standards. So selective testing is sufficient. The fabric is made of yarn. Yarn can be divided into short fiber, medium-long fiber and filament according to its length. No matter which state, it is not suitable for direct weaving. Therefore, before weaving, the yarn will be sized to make the yarn stiff, improve strength, reduce hairiness and improve wear resistance. Only in this way can the weaving process be carried out smoothly. After weaving, these sizing materials and various oil stains and stains generated in the weaving process need to be washed clean before dyeing to ensure the uniformity of dyeing and dyeing rate. Does the dye attached to the surface of the fiber increase the weight of the yarn? In the post-finishing, static agents, softeners, static agents, waterproofing agents will be added. If the weight is deviated, some weight-increasing agents may even be added. These will change the weight of the yarn. Back to the front end, tens of thousands of warp yarns are made into warp beams. The warp yarns are also subjected to huge weaving tension during the weaving process. Under the action of tension, the yarns will be pulled thinner and longer. From grey cloth to finished product, it is also necessary to go through some processes such as pre-shrinking, shaping, and width expansion. That is to say, the yarn needs to be stretched and contracted repeatedly during the production process; from the definition of yarn count, whether it is a fixed weight system or a fixed length system, these either change the weight or the length. In summary, the recommended technical requirements are. [Yarn twist] ● Detection importance: not recommended ● Technical requirements: ±10% recommended Yarn twist, short fiber yarn, single yarn is to improve the spinnability of the fiber through twist; using ply yarn can improve the yarn strength, and when the twist direction is consistent, it can improve the surface gloss of the fabric; chemical fiber filament generally does not require twist, and can also improve spinnability by adding weak twist or network points. There are two types of twist tests: direct counting method and untwisting and twisting method. For ply yarn, the direct counting method has more accurate test results. It is not recommended to test the twist of short fiber single yarn. The test result deviation is too large. It can only be used as a reference and there is no way to get an accurate value. Filament is similar, but short fiber yarn is slightly more accurate. 【Fabric Density】● Test Importance: Selective Test● Technical Requirements: ±5% Fabric density refers to the number of warp or weft yarns within a certain length (10 cm or 1 cm in China, 1 in abroad); the density of warp and weft can determine many physical properties of the fabric, such as weight, tensile strength, tear strength, and seam slip performance, etc.; it is an important parameter in the fabric. The warp density is mainly affected by the width. If the total number of warp roots is certain, the warp density will inevitably change if the width increases or decreases; if the warp density increases, it means that the width has become smaller, and the shrinkage rate will also decrease accordingly; the tensile strength will also increase; at the same time, the tear strength will also decrease, and the seam slippage parallel to the warp direction will also deteriorate accordingly. For the weft yarn, the weft density decreases, which means that the cloth has become longer, the corresponding shrinkage rate has increased, and the tear strength will also deteriorate accordingly.So the test data, if you can understand it, it will speak. 【Weave Classification】● Importance of Detection: Not Recommended● Technical Requirements: NoneThat is, the organizational structure, 1/1 plain, 1/2 twill, 2/2 twill, etc., the weave classification has been analyzed before the fabric production, and basically there will be no mistakes, and even if it is wrong, the woven fabric style is completely wrong. In addition, there are no relevant standard requirements in the national or foreign standards. So it is not recommended to test this. I personally think it is completely meaningless. Who would make a mistake with this? 【Weight】● Importance of Detection: Recommended to test● Technical Requirements: Recommended ±5% is also called unit area mass. The square meter mass is commonly used in China, and the square yard mass is also used abroad. The unit is: ounce/square yard. 1 ounce per square meter (OZ/y2) = 33.9 grams per square meter (g/m2) Gram weight is still necessary to assess, especially for fabrics used in some special fields. The gram weight is not allowed to exceed too much, otherwise the quality of the entire product will be overweight, for example: portable tents. I think it is also necessary for clothing. Clothing can’t be made heavier and heavier. It’s better to be lighter. During the production process, the gram weight is also changeable, and there are often large deviations at the head, middle and tail, including the same door, left and middle. If there is a difference in the gram weight of single-dyed fabrics, first check whether the warp and weft density are consistent. If there is a difference in coated fabrics, it is necessary to check whether the thickness is consistent. If it is cotton or linen fabrics, you may also need to check the yarn count. Various situations may exist, just check accordingly. [Fabric Thickness] ● Importance of detection: selective testing ● Technical requirements: According to customer requirements, give specific positive and negative values. I personally think that only coated fabrics and fabrics used in some specific fields are tested; mainly control the fabric density and coating thickness. [Width and effective width] ● Importance of detection: selective testing ● Technical requirements: not less than customer requirements. The width refers to the distance from the leftmost to the rightmost in the width direction of the fabric; because the fabrics need to be fixed on both sides during production and processing, this fixing method is so that pinholes will definitely appear on both sides; the effective width is the width that can be used after removing the pinholes. The width mainly affects the layout in the later garment-making process and increases the utilization rate of fabrics; therefore, the customer’s effective width must be met, otherwise it may cause waste of fabrics.

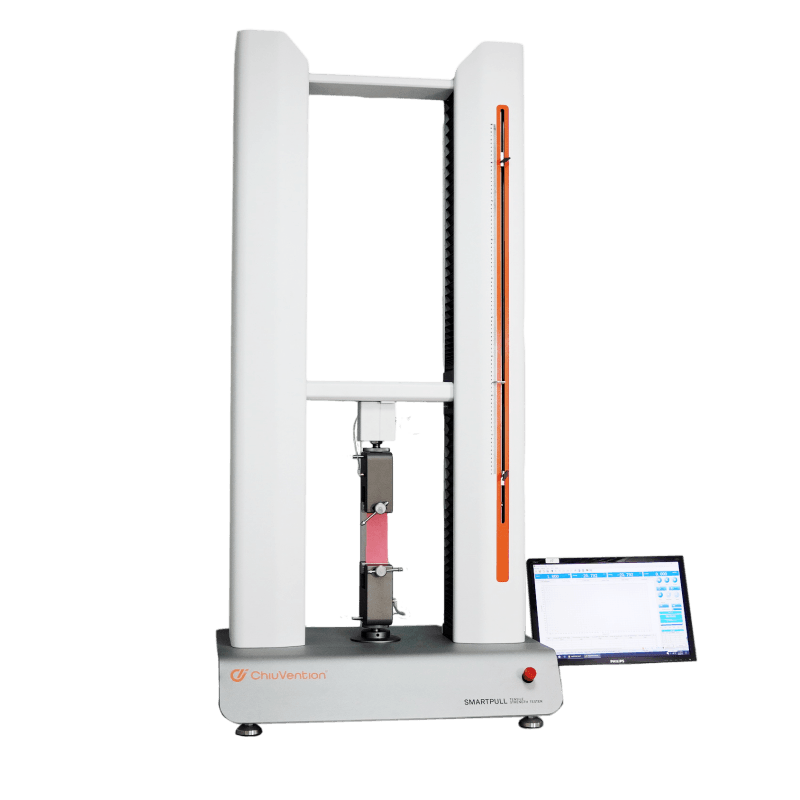

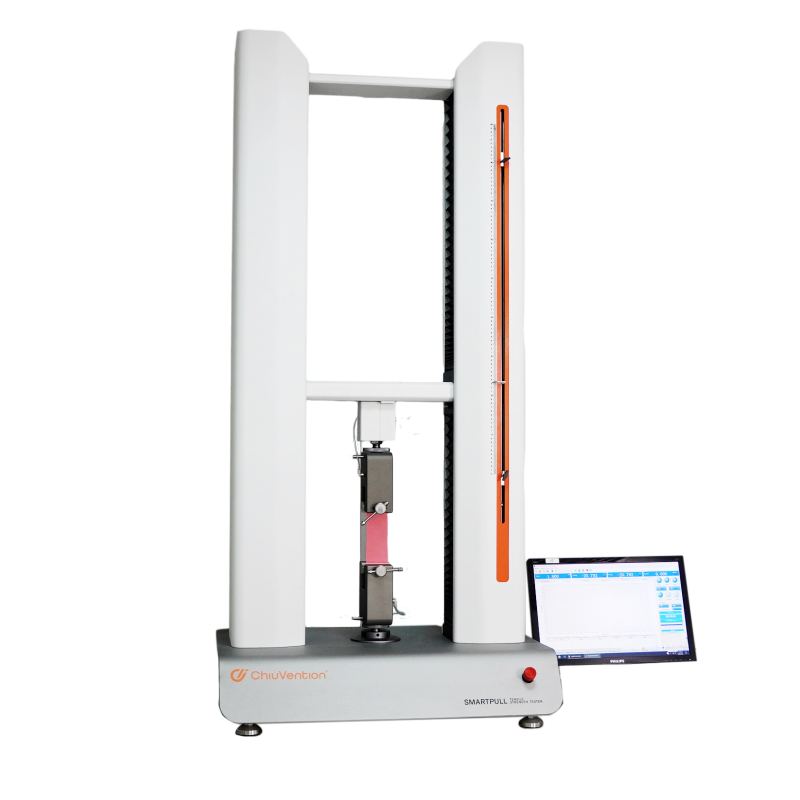

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: [email protected]